Maintaining a kegerator might seem like a daunting task, but fear not! This article will dispel any concerns you may have about the level of difficulty involved. Whether you’re a seasoned beer enthusiast or just starting your keg journey, we’ll explore the ins and outs of kegerator maintenance, providing you with helpful tips and tricks along the way. So sit back, relax, and prepare to learn how to keep your kegerator running smoothly without breaking a sweat.

CHECK OUT MINI FRIDGES AND KEGERATORS ON AMAZON

Understanding Kegerators

What is a kegerator?

A kegerator is a refrigerator or a specially designed appliance that allows you to store and serve draft beer at home. It is essentially a combination of a keg of beer and a cooling unit. With a kegerator, you can enjoy the freshness of draft beer in the comfort of your own home.

How does a kegerator work?

The basic principle behind a kegerator is simple. It consists of a cooling unit that cools the beer keg inside the appliance, keeping it at the optimal temperature for serving. The cooling unit is connected to a tap faucet, which is used to pour the beer. A CO2 tank is also part of the system, providing the necessary pressure to push the beer from the keg to the tap faucet.

Types of kegerators

There are different types of kegerators available in the market, catering to different needs and preferences. The most common types include:

- Full-size Kegerators: These are large units that can accommodate multiple kegs. They are the ideal choice for those who frequently entertain or have a dedicated space for their kegerator setup.

- Mini Kegerators: These are smaller, compact units that can fit on a countertop or table. They are suitable for those who have limited space or want a portable option.

- Outdoor Kegerators: Designed specifically for outdoor use, these kegerators are built to withstand different weather conditions.

- Built-in Kegerators: These kegerators are designed to be installed in a cabinet or under the counter, providing a seamless and integrated look in your kitchen or bar area.

Common Maintenance Tasks

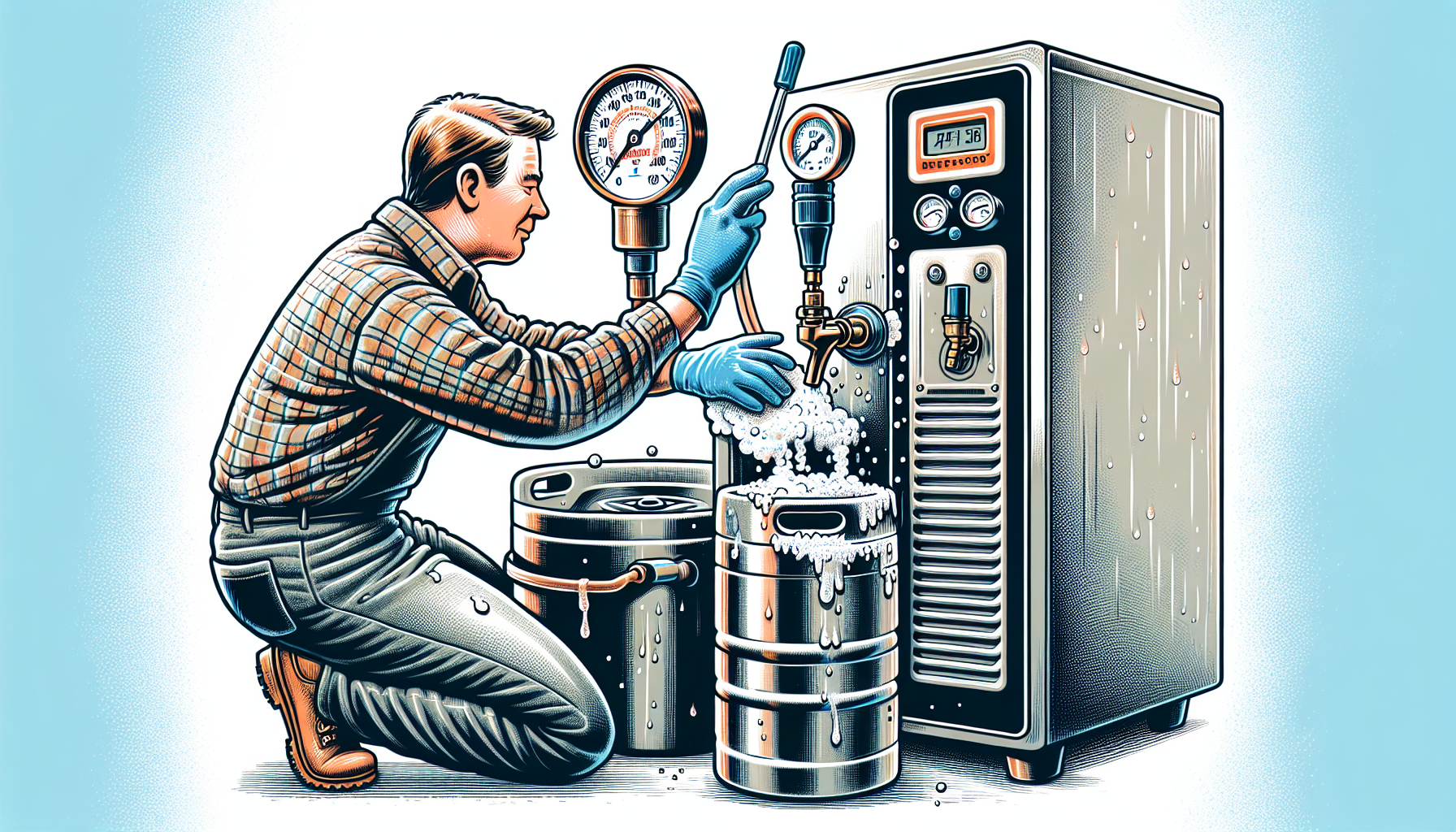

Cleaning the kegerator

Regular cleaning is essential to maintain the quality and taste of the beer. Cleaning the kegerator involves removing any residual beer, dirt, or bacteria that may have accumulated. It is recommended to clean the kegerator every time you change the keg to prevent any buildup.

Sanitizing the kegerator

Sanitizing goes beyond cleaning and involves ensuring that harmful bacteria and contaminants are eliminated. This step is crucial to maintain the freshness and quality of the beer. Sanitizing the kegerator should be done periodically, typically every three to six months, or as recommended by the manufacturer.

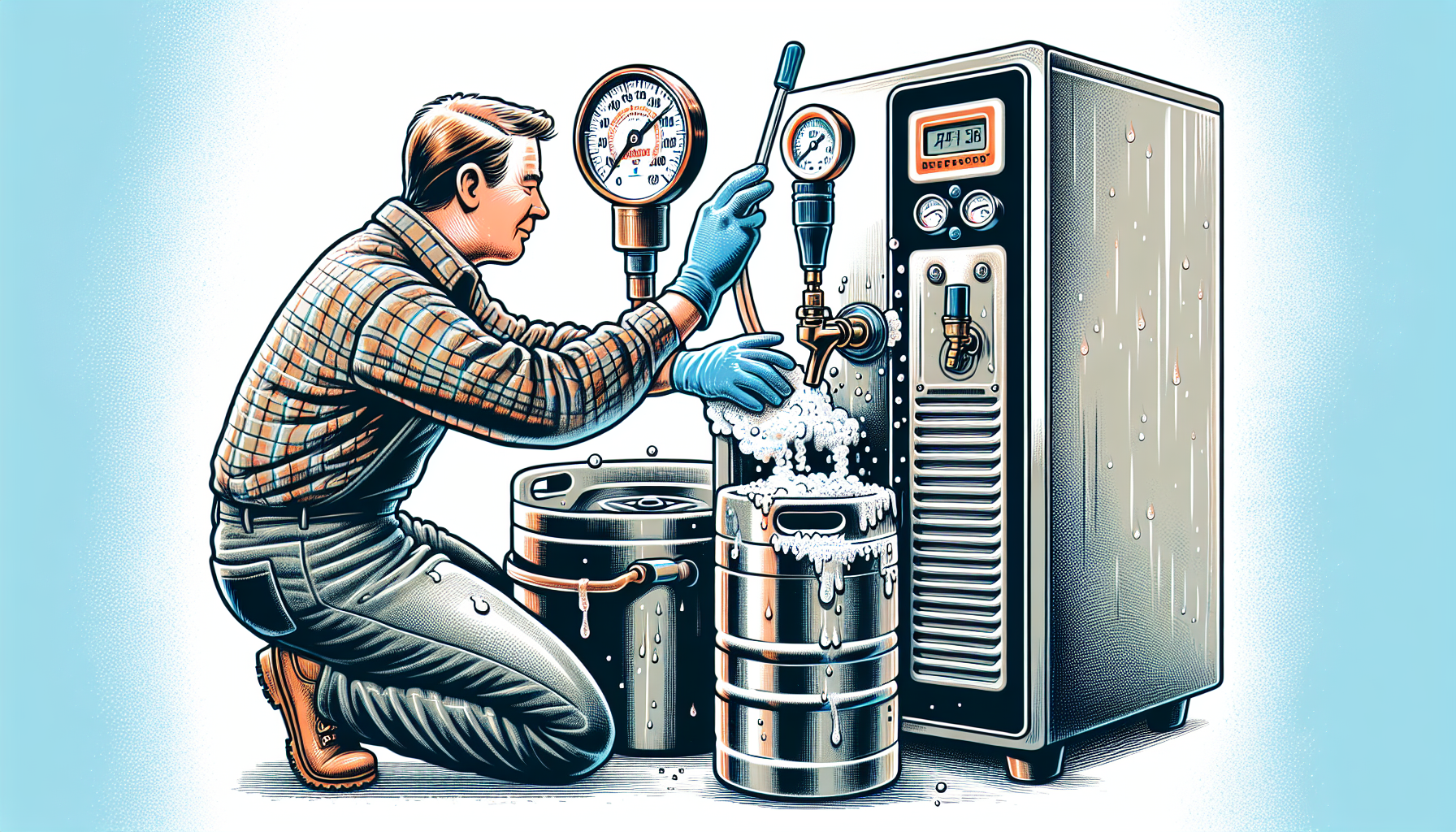

Checking CO2 levels

CO2 is used to carbonate the beer and push it out of the keg. It is important to regularly check the CO2 levels to ensure optimal carbonation and dispensing of the beer. Low CO2 levels can result in flat beer, while high levels can lead to over-carbonation and foaming issues.

Temperature control

Maintaining the right temperature is vital for preserving the quality and taste of the beer. The kegerator should be set to the recommended temperature range for the specific type of beer being stored. Regularly monitoring and adjusting the temperature settings will help keep the beer at its peak condition.

Cleaning the Kegerator

Cleaning the beer lines

One of the key components of a kegerator is the beer lines, which connect the keg to the tap faucet. Over time, these lines can become dirty and harbor bacteria if not properly cleaned. Regularly cleaning the beer lines will help prevent off-flavors and ensure the beer flows smoothly.

Cleaning the tap faucet

The tap faucet is the point of contact between the beer and the glass, making it essential to keep it clean. Buildup of residue and bacteria in the tap faucet can affect the taste and quality of the beer. Cleaning the tap faucet regularly will ensure clean and flavorsome pours.

Cleaning the keg coupler

The keg coupler is the device that attaches the keg to the kegerator and regulates the flow of beer. It is important to clean the keg coupler, especially the internal components, to prevent contamination and maintain proper function. Regular cleaning will help ensure smooth operation and prevent any issues with the dispensing of the beer.

Cleaning the drip tray

The drip tray catches any spilled beer or condensation, preventing it from dripping onto the floor. Regularly cleaning the drip tray will ensure proper hygiene and prevent any unpleasant odors. It is also important to empty and clean the drip tray after each keg change to prevent any buildup.

Sanitizing the Kegerator

Importance of sanitization

Sanitizing the kegerator is an essential step in maintaining the quality and taste of the beer. It helps eliminate any bacteria or contaminants that may be present, ensuring that the beer remains fresh and safe to consume. Proper sanitization also helps prevent off-flavors and keeps the kegerator in optimal condition.

Sanitizing solutions

There are various sanitizing solutions available in the market specifically designed for kegerators. These solutions are typically food-grade and safe to use. It is important to follow the manufacturer’s instructions and use the recommended sanitizing solution for effective sanitization.

Steps to sanitize the kegerator

To sanitize the kegerator, start by removing any remaining beer or cleaning solution from the system. Next, prepare the sanitizing solution as per the instructions. Use a clean cloth or sponge to thoroughly wipe down all the surfaces, including the keg coupler, beer lines, tap faucet, and drip tray. Allow the sanitizing solution to sit for the recommended duration before rinsing it out with clean water. Finally, let the kegerator air dry or use a clean cloth to dry it completely before reconnecting the keg.

Checking CO2 Levels

Why is it important?

Checking the CO2 levels is crucial to ensure proper carbonation and dispensing of the beer. Low CO2 levels can result in flat beer, while high levels can lead to excessive foaming and over-carbonation. Maintaining the correct CO2 levels will optimize the taste and quality of the beer, providing a satisfying drinking experience.

How to check CO2 levels

To check the CO2 levels, start by turning off the gas supply to the kegerator. Attach a CO2 pressure gauge to the regulator, ensuring a secure connection. Slowly turn on the gas supply and observe the gauge. The recommended CO2 pressure will vary depending on the beer style and personal preference. Consult the appropriate resources or the keg manufacturer’s guidelines for the recommended CO2 pressure range.

Adjusting CO2 pressure

If the CO2 levels are too low, adjust the pressure by turning the regulator clockwise. If the CO2 levels are too high, turn the regulator counterclockwise to lower the pressure. Make small adjustments and allow the system to stabilize before checking the CO2 levels again. It may take some trial and error to find the optimal pressure for your specific setup and preferences.

Maintaining Temperature

Temperature control importance

Proper temperature control is vital for preserving the freshness and quality of the beer. Each type of beer has an optimal serving temperature range, and maintaining the beer within that range ensures the best flavor and aroma. Fluctuations in temperature can negatively impact the taste and cause the beer to go flat or develop off-flavors.

Calibrating the thermostat

It is important to regularly calibrate the thermostat of the kegerator to ensure accurate temperature readings. To calibrate the thermostat, use a separate thermometer to check the actual temperature inside the kegerator. If there is a difference between the thermostat reading and the separate thermometer reading, adjust the thermostat accordingly to align them.

Handling temperature fluctuations

To minimize temperature fluctuations, it is important to place the kegerator in a location away from direct sunlight and heat sources. Ensure proper insulation and use a fan, if necessary, to circulate the air inside the kegerator. Additionally, avoid frequent opening and closing of the kegerator door, as it can result in temperature variations. Regularly monitor the temperature and make adjustments as needed to maintain the desired range.

Replacing Parts

When to replace parts

Over time, certain parts of the kegerator may wear out or become damaged. It is essential to replace these parts to ensure optimal performance and functionality. Signs that indicate the need for part replacement include leaks, reduced pressure, inconsistent temperature control, or poor dispensing of beer.

Replacing seals and gaskets

Seals and gaskets play a crucial role in maintaining a tight seal and preventing leaks in the kegerator. If you notice any signs of wear or damage, such as cracks or tears, it is important to replace them. The process for replacing seals and gaskets may vary depending on the specific kegerator model, so refer to the manufacturer’s instructions for guidance.

Replacing beer lines

Beer lines can become dirty or develop mold or bacteria over time, affecting the taste and quality of the beer. If cleaning is no longer effective, it may be necessary to replace the beer lines. This process typically involves disconnecting and removing the old lines and installing new ones. Refer to the manufacturer’s instructions for the specific steps for your kegerator model.

Maintaining the tap faucet

The tap faucet is an integral part of the kegerator, and proper maintenance is crucial to ensure smooth operation. Regularly inspect the tap faucet for any signs of wear, such as sticky handles or leaks. Clean the faucet regularly and replace any worn-out or damaged parts as needed.

Preventing Common Issues

Avoiding foamy beer

Foamy beer can be disappointing and frustrating. To prevent excessive foaming, ensure that the beer lines are clean and free from residue or blockages. Additionally, check and adjust the CO2 pressure to the appropriate levels. Temperature control is also essential, as warmer temperatures can cause the beer to foam excessively.

Preventing beer lines from freezing

If your kegerator is located in a cold environment or exposed to low temperatures, it is important to take precautions to prevent the beer lines from freezing. Insulate the beer lines and consider using a heat wrap or tape to provide additional insulation. Regularly monitor the temperature to ensure it remains above freezing levels.

Handling leaks and drips

Leaking or dripping can occur due to various reasons, such as loose connections, damaged seals, or faulty parts. Regularly inspect the kegerator for any signs of leaks or drips. Tighten any loose connections or replace any damaged seals. If the issue persists, consult the manufacturer’s instructions or seek professional assistance.

CHECK OUT MINI FRIDGES AND KEGERATORS ON AMAZON

Troubleshooting

Identifying common problems

Understanding and identifying common problems can help troubleshoot and resolve issues quickly. Some common issues include inconsistent temperature control, excessive foaming, low or high carbonation, leaks or drips, and off-flavors. By identifying the specific problem, you can take appropriate steps to troubleshoot and resolve the issue.

Troubleshooting temperature issues

If you’re experiencing temperature control issues, start by checking the thermostat settings and calibrating if necessary. Ensure proper insulation and ventilation of the kegerator. Clean any condenser coils or fans that may be obstructed. If the issue persists, consider contacting the manufacturer or seeking professional assistance.

Fixing carbonation problems

Carbonation issues can occur if the CO2 levels are too low or too high. Start by checking the CO2 pressure and adjusting it as needed. Ensure that the beer lines and keg coupler are clean and free from any obstructions. If the issue persists, consider consulting the keg manufacturer’s guidelines or seeking professional assistance.

Conclusion

Regular maintenance and care are essential to ensure the optimal performance and longevity of your kegerator. By understanding the various maintenance tasks, such as cleaning, sanitizing, checking CO2 levels, maintaining temperature, and replacing parts when necessary, you can enjoy fresh and delicious draft beer in the comfort of your own home. With proper maintenance, a kegerator can be an easy and enjoyable addition to your home bar or entertainment space. Cheers to good beer and hassle-free kegerator maintenance!